Tailings Progress Report: Implementing the Global Industry Standard on Tailings Management (GISTM)

ICMM’s Tailings Progress Report aggregates data from our members’ August 2025 disclosures, offering a transparent snapshot of collective progress towards full conformance with the GISTM, and sharing case studies from members’ implementation and their wider work to reduce tailings, to support wider industry. It does not provide company-level information or the conformance status of individual facilities – this data is available in each company’s disclosure.

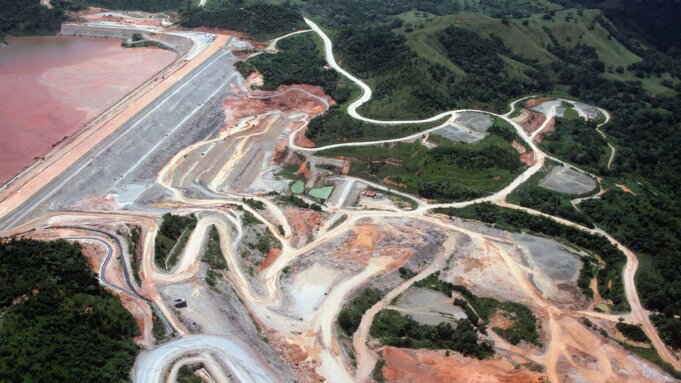

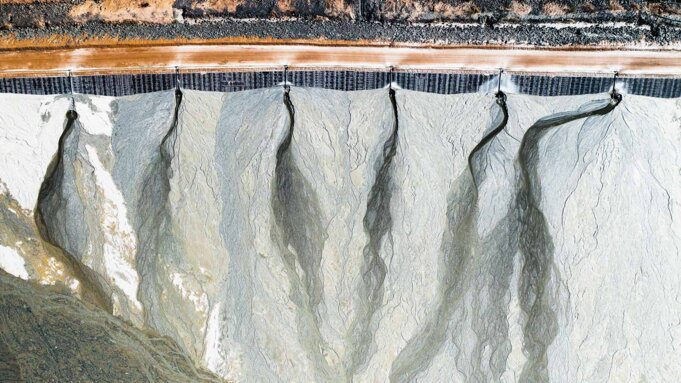

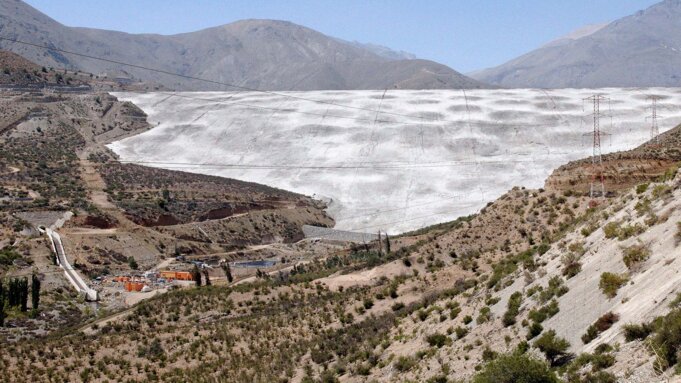

- The GISTM was developed to prevent catastrophic failures and enhance the safety of mine tailings facilities worldwide. When it was published in 2020, ICMM members committed that all tailings facilities with an ‘extreme’ or ‘very high’ consequence classification would conform with the GISTM by August 2023, and all other applicable tailings facilities by August 2025. This commitment galvanised immediate and sustained action by ICMM members, towards achieving and maintaining conformance with the GISTM.

- In August 2025, all ICMM members individually disclosed the status of conformance for each of their facilities, and a summary of timebound measures to address any gaps, alongside the GISTM mandated disclosures

- Analysis of ICMM members’ 2025 disclosures shows that while significant progress has been made, achieving full conformance with the GISTM is taking more time than initially anticipated, and remains a work in progress.

-

Out of the total of 836 ICMM member facilities, 67 per cent are in full conformance with the GISTM, while 33 per cent remain in partial conformance.

-

Having made the decision to prioritise implementing the GISTM at tailings facilities that would have the highest consequences downstream in the event of a failure, ICMM members have made the greatest progress with the facilities classified as ‘extreme’ and ‘very high’ consequence, with over 80 per cent of ICMM member ‘extreme’ or ‘very high’ consequence classification tailings facilities in full conformance. ‘High’, ‘significant’, and ‘low’ consequence classification facility conformance ranges from 53-65 per cent.

-

- The system level change within companies that it has driven is unprecedented – fundamentally reshaping how tailings facilities are managed and requiring significant resource and time. ICMM member implementation of the GISTM has already resulted in transformative improvements in tailings engineering, management and governance – elevating tailings management to the highest levels of company oversight and accountability, while promoting greater transparency, collaboration, and meaningful engagement with stakeholders.

- The journey to safer tailings facilities and conformance with the GISTM doesn’t have an end point. Tailings management is inherently a process of continuous improvement - for example, even maintaining conformance with the GISTM once it’s been achieved demands routine review and auditing, as tailings facility operations are dynamic. Successful outcomes will be built not only on unwavering long-term commitment by companies, but also close collaboration between the industry, its financers, governments, civil society and communities local to sites.