Critical Control Management

In recent years, many mining companies have achieved significant improvements in health and safety performance.

Injury frequency rates are down, and reporting of both leading and lagging indicators is more consistent than ever.

But headline numbers don’t tell the whole story.

Despite progress, material unwanted events (MUEs)—such as underground fires, rockfalls, coal dust explosions and toxic exposure—continue to occur. These are high-consequence incidents that can lead to serious injuries, loss of life, and environmental damage.

In nearly every case, investigations reveal the same pattern: the controls needed to prevent these events were known—but not effectively implemented.

Analysis of ICMM company member organisational factors (2017-2023)

Data offers insights into the repeat causes of fatalities:

Failure to Follow Rules and Procedures: Not following established rules and procedures can cause serious harm to people, equipment and operations. These failures often point to broader systemic issues such as inadequate training, weak enforcement or poor communication. Addressing root causes is essential to prevent recurrence.

Design: Design covers the planning and engineering of equipment, systems and processes that prioritise safety, usability and compliance. Incidents often stem from design flaws, insufficient safety features, lack of human factors integration, and regulatory non-compliance. Effective design identifies and mitigates issues early.

Safety Culture: Safety culture reflects the shared beliefs, values and behaviours that influence how safety is prioritised. A strong culture features open communication, trust and proactive action. Gaps between policy and practice, complacency or poor responses to risks can lead to serious incidents.

Risk Management: Risk management involves identifying, assessing and controlling hazards to reduce the chance of incidents. It goes beyond routine procedures, focusing on early identification and continuous monitoring. Failures often occur due to weak assessments, missing controls or poor oversight.

Maintenance Management: This refers to the planning, delivery and oversight of maintenance to keep equipment safe and reliable. Incidents often arise from poor scheduling, inadequate execution, missing records, or untrained personnel. Maintenance must be systematic and well-resourced.

Contractor Management: Managing contractors involves setting clear expectations, ensuring compliance, and integrating them into company systems. Incidents are often linked to weak vetting, limited training, poor communication or lack of oversight. Clear alignment between all parties is critical.

Why traditional safety systems fall short

Safety management systems are often dense, complex, and burdened by lengthy risk registers and procedural checklists. In practice, this can make it hard for frontline teams to know:

- Which risks are most critical.

- What controls matter most.

- Who is responsible for making sure they work.

The result? Gaps in implementation, missed warning signs, and controls that fail under pressure.

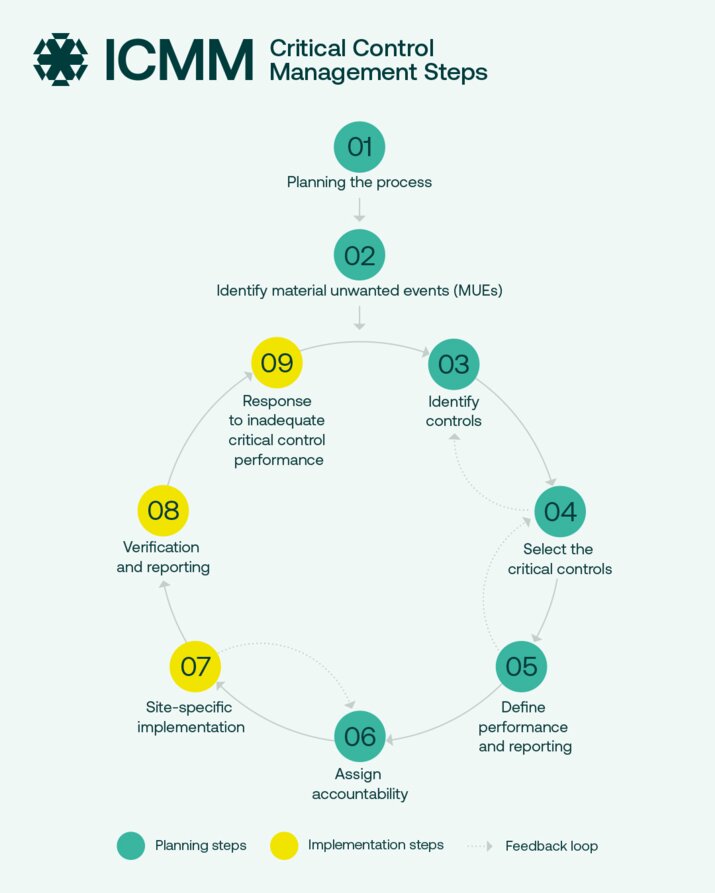

A focus on critical controls

Critical Control Management (CCM) flips the script. Rather than treating all controls equally, it identifies and prioritises the few that are absolutely essential to preventing a specific MUE.

A critical control is not just any measure—it’s one that must work to stop a fatal or catastrophic event from occurring. If that control fails, the consequences are severe.

The core principles of CCM

Effective critical control management approach requires:

- Clear identification of critical controls: Know which ones truly prevent harm.

- Defined performance expectations: Understand what each control must do to be effective.

- Verification and monitoring: Implement checks to confirm the controls are working.

- Assigned accountability: Make it explicit who is responsible for each control.

- Transparent reporting: Track and communicate how controls are performing.

It's about making sure that the right actions happen, at the right time, by the right people. ICMM’s Critical Control Management: Good Practice Guide provides a step-by-step roadmap to embed this approach.

Importantly, the guidance does not dictate which controls to use, because every site and every hazard is different. Instead, it offers a robust process to help companies identify the right controls for their specific risks—and build the systems needed to make them effective.

From compliance to confidence

Critical control management is not just another layer of risk documentation. It’s a fundamental shift in how safety is delivered.

By simplifying systems and focusing only on what truly matters, companies can move from compliance-based safety to performance-based prevention—creating safer workplaces and reducing the risk of catastrophic failure.